20# I-beam

20# I-beam is a kind of steel with special cross-section shape, its shape is similar to the English letter "work" and named. The cross-section of an I-beam is in the shape of an I-beam, consisting of a narrow rectangular section and two outwardly protruding flanges whose width is greater than the height of the web

Keywords:

Series:

Product Details

Products

20# I-beam is a kind of steel with special cross-section shape, its shape is similar to the English letter "work" and named. The cross-section of an I-beam is in the shape of an I-beam, consisting of a narrow rectangular section and two outwardly protruding flanges whose width is greater than the height of the web. With good structural strength and stability, I-beams are often used to fabricate structural members that need to withstand heavy loads and pressures, such as bridges, high-rise buildings and large-span industrial facilities. Due to its excellent load carrying capacity and stability, I-beams are widely used in construction, machinery, electric power and transportation.

parameter table

| Product Name | I Beam |

| Standard | GB/T 706-2016,JIS G3192-2008, ASTM, EN, etc. |

| Shape | I-shaped |

| Technique | Hot rolled |

| Material | Q235B, SM490, SS400, Q345B, 10#, 20#, 35#, 45#. |

| Width | 60-200mm |

| Height | 100-400mm |

| Web Thickness | 6-17.5mm |

| Theoretical Weight | 8.18kg/m-55.8kg/m |

| Classification | Ordinary I-beam and light I-beam |

| Feature | Large cross-section, high strength, light weight |

| Application | Various civil and industrial building structures |

Application:

Profile is iron or steel and a certain strength and toughness of the material through rolling, extrusion, casting and other processes made of objects with a certain geometric shape. This type of material has the appearance of a certain size, cross-section of a certain shape, with certain mechanical and physical properties. Profiles can be used alone or further processed into other manufactured products, commonly used in building structures and manufacturing installation. Mechanical engineers can select the specific shape, material, heat treatment status, mechanical properties and other parameters of the profile according to the design requirements, and then according to the specific size and shape requirements of the profile will be divided, and then further processed or heat-treated, to achieve the design of the precision requirements. The material, specification and size of the profile can refer to the corresponding national standards.

Profile production has the following characteristics:

(1) varieties of specifications. Has amounted to more than 10,000 kinds, and in the production, in addition to a small number of special mills to produce specialized products, the vast majority of profile mills are in the multi-species, multi-specification production.

(2) large differences in section shape. In the profile products, in addition to square, round, flat steel section shape is simple and not much difference, most of the complex section profiles (such as I-beam, H-beam, Z-beam, channel steel, rails, etc.) is not only the complex section shape, but also a large difference between each other, the design of the holes in these products and rolling production have their own specificity; the complexity of the shape of the section so that the deformation of all parts of the metal during the rolling process, the distribution of the section temperature As well as roll wear and other uneven, so it is difficult to accurately calculate the size of the rolled parts and control, mill adjustment and guide device installation is also more complex; in addition to the complex section profiles of individual varieties or specifications are usually smaller batches. The above factors make the development of complex section profiles continuous rolling technology is difficult.

(3) The structure of the mill and mill layout form more. In the form of structure, there are two-roll mill, three-roll mill, four-roll universal hole type mill, multi-roll hole type mill, Y-type mill, 45 ° mill and cantilever mill. In the form of mill layout in a horizontal row of mills, column mills, checkerboard mills, semi-continuous mills and continuous mills and so on.

Pack and Ship

Customer Evaluation

Over the years, we strive for survival by quality and development by efficiency, adhering to the business philosophy of "integrity, pragmatism, innovation and development", and have repeatedly won praise from customers.

FAQ

Are you a manufacturing company or a trading company?

We are a manufacturer of metal materials and products with many years of experience.

Can you provide samples?

We can provide free samples, but samples are subject to a sample fee, which is refundable upon order confirmation.

How can I get an accurate quotation?

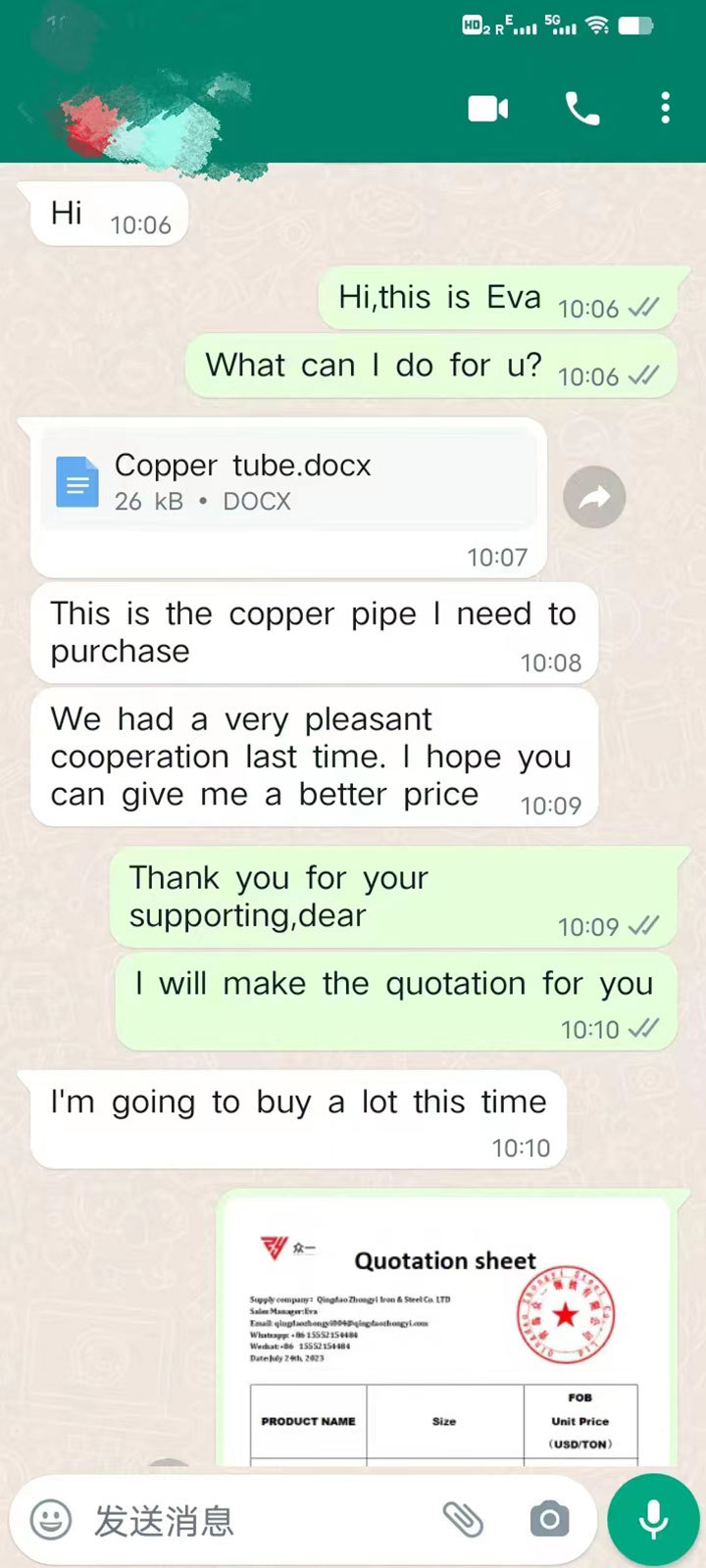

Please provide the product standard, material, size, quantity and other information.

What kind of payment terms do you accept?

We can accept T/T, L/C, Western Union or negotiation.

What markets do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa, etc

Can you deliver the goods on time?

Yes, whether the price changes or not, we guarantee to provide the best quality products and on time delivery. Integrity is the purpose of our company.

Factory

Shandong Zhongyi Metal Products Co., Ltd. is an enterprise specializing in the research and development, production, sales and service of metal products. Located in Shandong Province, China, the company covers a vast area with advanced production equipment and testing instruments, and a team of skilled and strong staff.

Zongyi Metal Products Co., Ltd. mainly produces all kinds of metal products, serving the industries of precision machinery parts, automobile parts, electronic components, construction and decoration materials. Adhering to the business philosophy of "Quality is the foundation, Innovation is the soul", the company constantly introduces advanced technology and equipment to improve product quality and reduce production costs to meet customer needs.

We have rich experience in the metal products industry, and our products sell well in domestic and international markets and are well received by customers. We always adhere to the customer-centered, market-oriented, in order to survive, innovation and development. We are willing to cooperate with customers at home and abroad to create a better future.

factory

factory

factory

Previous Article

Next Article

Previous Article

Next Article